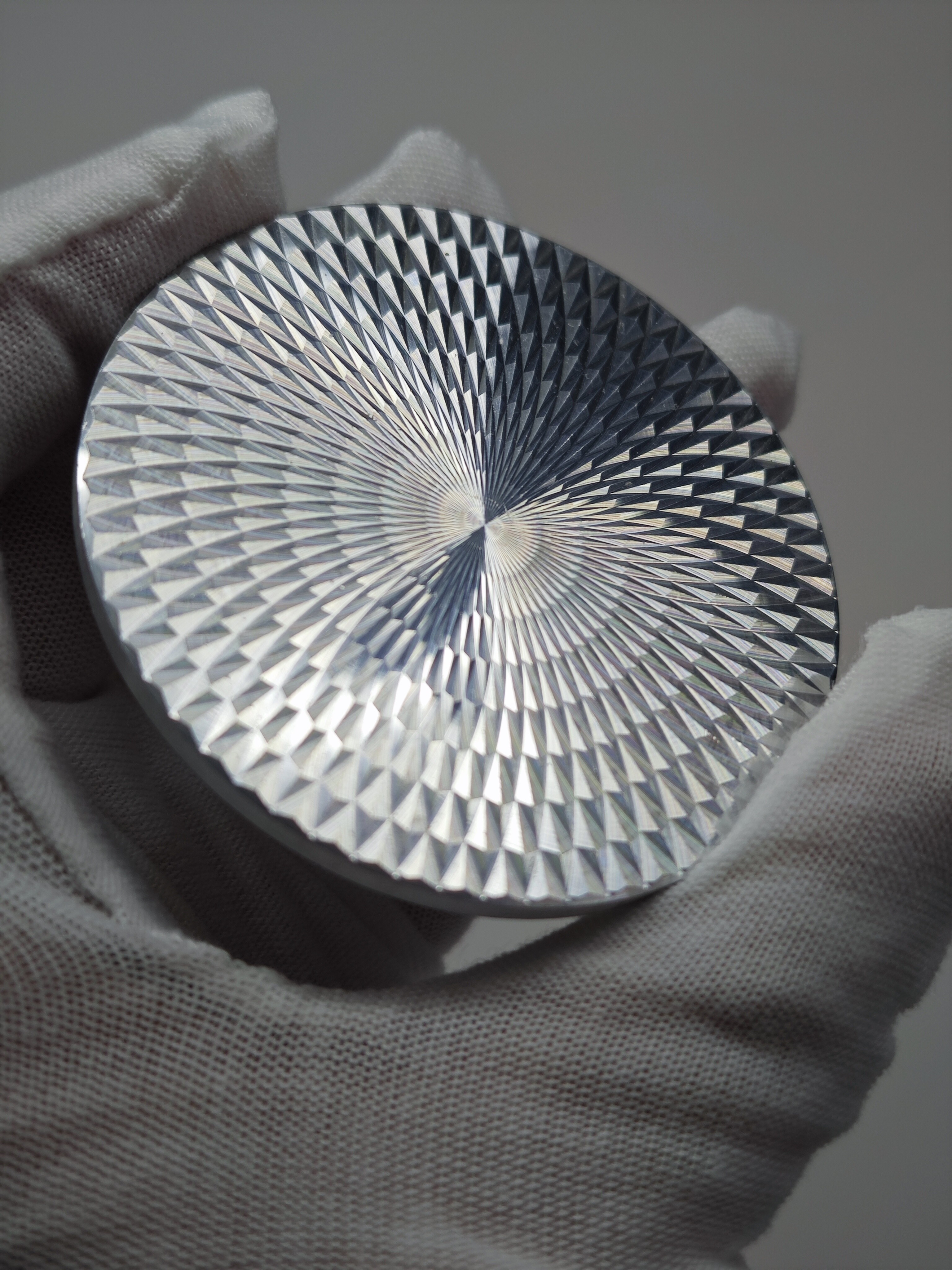

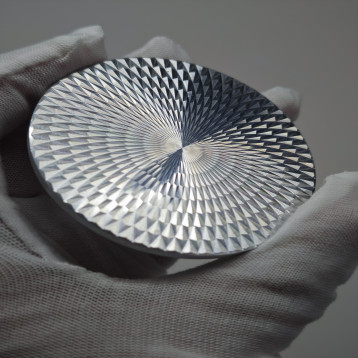

"Special patterns" in CNC manufacturing represent the intersection of technical artistry, functional innovation, and manufacturing excellence. These are not standard textures but engineered surfaces created through intentional toolpath strategies, custom tooling, or hybrid processes that transform ordinary milled and turned parts into exceptional components.

Implants: Bone ingrowth surfaces, identification patterns

Surgical Tools: Directional grip patterns, torque enhancement

Diagnostic Equipment: Optical alignment patterns, calibration marks

Engine Components: Cooling enhancement patterns, weight reduction textures

Control Surfaces: Boundary layer control patterns, inspection aids

Fasteners: Tamper-evident patterns, installation indicators

Housings: Brand signature textures, functional grips

Controls: Tactile feedback patterns, wear indicators

Connectors: Insertion force control patterns, alignment features

Interior Components: Haptic feedback surfaces, decorative accents

Under-hood Parts: Heat dissipation patterns, fluid flow directors

Wear Components: Lubricant retention patterns, wear indicators